Folding Adirondack Chair Downloadable Woodworking Plan

Folding Adirondack/Muskoka Chair Downloadable Patterns

From your leading supplier of woodworking patterns, clock parts and many more low priced woodworker supplies.

|

|

|

|

Regular 65 degree angle |

Reclined 50 degree angle |

Folded to 12 1/4" |

A Better Designed, More Comfortable Adirondack Chair

Message from the designer of these downloadable woodworking plans

"Unlike a regular Adirondack chair, where there are many different styles, most folding chairs seems to be fairly similar in the way they fold. Unfortunately, most chairs that I have seen, utilize the "flipper" behind the back support. Most of these chairs are bolted using one washer, or none, in between the folding parts. Some designs rub on the sides of the main frame support, and over time show scraping marks, and can also bind if folded after moist weather.

In designing this chair, I felt it was important to keep the integrity of the original chair design, with the tapered back support. Since I, and many fellow Canadian cottagers, prefer to paint our chairs in bright colors, it was also important that there was sufficient space between the folding parts, yet keeping the structural strength.

In experimenting with various options, including nylon futon bushings and metal porch glider mechanisms, I found an inexpensive and strong solution to the needs of this design. While you can still build this chair using regular carriage bolts with washers between the folding parts, over time the holes may get larger and the chair may get sloppy."

The plans include the alternate use of carriage bolts encased in polyethylene tubing and custom made 1/4" washers, using UHMW plastic, used for table saw and router jigs for smooth movement. All parts are readily available at leading woodworking supply and hardware stores.

About this Adirondack chair:

The left-hand image above, showing the chair in the upright position, is identical to the original in position and comfort. The image in the middle shows the chair reclined to 50 degrees....a very comfortable snoozing position. The back is supported by the arms and curved back seat slat, and all pieces are screwed and glued with Gorrilla Glue for the necessary strength. A recent customer picked up some plans at my home and sat in one of the final prototypes. He found it very comfortable in the reclined position, and strong enough to hold his over 6' height and 210 lb. weight.

The right hand image shows the chair folded to 12 1/4" (32 cm) and can hang on the wall of my garage.To fold the chair, push on the back and walk it forward into the folded position. To open the chair, pull up on the back. The chair will open to the reclined position, then pull on the back support to put it in the regular 65 degree angle. To recline the chair, while sitting in it, reach back and pull the back support forward. Lean back and relax!

If you are using your chairs on uneven ground or on the beach, you may want to add stop locks to the back supports. This will eliminate the back from reclining into the sand. To fold the chair, push the back support forward to unlock it, and fold forward.

The chair can be constructed of 3/4" (1.9cm) pine, cedar or redwood, with all pivot parts of 1/1/4" (3.2cm) stock for extra strength and gluing surface. Plans include pictures and dimensions of the taper sled I use on my table saw, to cut the back slats and back support pieces.

Assembled Dimensions - 32 1/2"W x 37"D x 38"H (82.6cmW x 94cmD x 96.5cmH)

This Woodworking Pattern Prints to Letter Size Paper.

Also Available in Autocad Size File. Click Here for Full Size Autocad Option

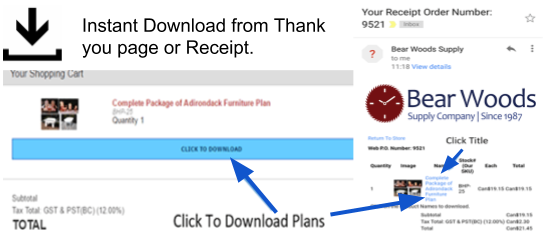

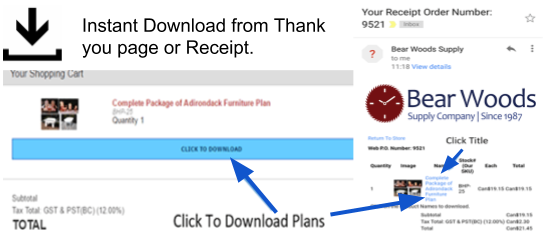

Download your scroll saw patterns right away! Click the link on the Thank You Page after your purchase completes, or Click the Name of the Scroll Saw Pattern in your Receipt email from Bear Woods Supply.

Write a Review || | Explore all

Featured positive reviews:

It is a great design however the Download does not give an actual size option so I had to make fullsize graph paper and translate. After that it was great.

Thank You

I have not made this project yet but am looking forward to doing so. The ordering was easy and downloading the plans couldn't have been simpler.

Great plans, very reasonable price and well presented

Folding Adirondack/Muskoka Chair Downloadable Patterns

From your leading supplier of woodworking patterns, clock parts and many more low priced woodworker supplies.

|

|

|

|

Regular 65 degree angle |

Reclined 50 degree angle |

Folded to 12 1/4" |

A Better Designed, More Comfortable Adirondack Chair

Message from the designer of these downloadable woodworking plans

"Unlike a regular Adirondack chair, where there are many different styles, most folding chairs seems to be fairly similar in the way they fold. Unfortunately, most chairs that I have seen, utilize the "flipper" behind the back support. Most of these chairs are bolted using one washer, or none, in between the folding parts. Some designs rub on the sides of the main frame support, and over time show scraping marks, and can also bind if folded after moist weather.

In designing this chair, I felt it was important to keep the integrity of the original chair design, with the tapered back support. Since I, and many fellow Canadian cottagers, prefer to paint our chairs in bright colors, it was also important that there was sufficient space between the folding parts, yet keeping the structural strength.

In experimenting with various options, including nylon futon bushings and metal porch glider mechanisms, I found an inexpensive and strong solution to the needs of this design. While you can still build this chair using regular carriage bolts with washers between the folding parts, over time the holes may get larger and the chair may get sloppy."

The plans include the alternate use of carriage bolts encased in polyethylene tubing and custom made 1/4" washers, using UHMW plastic, used for table saw and router jigs for smooth movement. All parts are readily available at leading woodworking supply and hardware stores.

About this Adirondack chair:

The left-hand image above, showing the chair in the upright position, is identical to the original in position and comfort. The image in the middle shows the chair reclined to 50 degrees....a very comfortable snoozing position. The back is supported by the arms and curved back seat slat, and all pieces are screwed and glued with Gorrilla Glue for the necessary strength. A recent customer picked up some plans at my home and sat in one of the final prototypes. He found it very comfortable in the reclined position, and strong enough to hold his over 6' height and 210 lb. weight.

The right hand image shows the chair folded to 12 1/4" (32 cm) and can hang on the wall of my garage.To fold the chair, push on the back and walk it forward into the folded position. To open the chair, pull up on the back. The chair will open to the reclined position, then pull on the back support to put it in the regular 65 degree angle. To recline the chair, while sitting in it, reach back and pull the back support forward. Lean back and relax!

If you are using your chairs on uneven ground or on the beach, you may want to add stop locks to the back supports. This will eliminate the back from reclining into the sand. To fold the chair, push the back support forward to unlock it, and fold forward.

The chair can be constructed of 3/4" (1.9cm) pine, cedar or redwood, with all pivot parts of 1/1/4" (3.2cm) stock for extra strength and gluing surface. Plans include pictures and dimensions of the taper sled I use on my table saw, to cut the back slats and back support pieces.

Assembled Dimensions - 32 1/2"W x 37"D x 38"H (82.6cmW x 94cmD x 96.5cmH)

This Woodworking Pattern Prints to Letter Size Paper.

Also Available in Autocad Size File. Click Here for Full Size Autocad Option

Write a Review || | Explore all

Featured positive reviews:

It is a great design however the Download does not give an actual size option so I had to make fullsize graph paper and translate. After that it was great.

Thank You

I have not made this project yet but am looking forward to doing so. The ordering was easy and downloading the plans couldn't have been simpler.

Great plans, very reasonable price and well presented

Download your scroll saw patterns right away! Click the link on the Thank You Page after your purchase completes, or Click the Name of the Scroll Saw Pattern in your Receipt email from Bear Woods Supply.

Add to Cart

Add to Cart

Cart

Cart